Maintenance for Infiltration Practices

J.L. Nieber, A.J. Erickson, P.T. Weiss, J.S. Gulliver, R.M. Hozalski

In the past, infiltration structures have been shown to have a relatively short lifespan. Over 50 percent of infiltration systems either partially or completely failed within the first 5 years of operation (U.S. EPA. 1999a). In a Maryland study on infiltration trenches (Lindsey et al. 1991), 53 percent were not operating as designed, 36 percent were clogged, and 22 percent showed reduced filtration. In a study of 12 infiltration basins (Galli 1992), none of which had built-in pretreatment systems, all had failed within the first two years of operation.

Actions

Infiltration basins and trenches

Common reasons cited for failure of infiltration trenches and basins include:

- Poor site selection

- Improper soil textures

- Lack of pretreatment structures

- Clogging of the soil

- Compaction of soil

- Improper maintenance of appropriate surface vegetation

The most commonly cited reason for failure of infiltration structures is clogging due to sediment and organic debris. Due to susceptibility of clogging, pretreatment of stormwater upstream of an infiltration basin or trench is recommended to remove sediments and debris (Minnesota Stormwater Manual). Pretreatment structures, such as a plunge pool, sump pit, filter strip, sedimentation basin, grass channel, or a combination of these practices should be installed upstream of the infiltration practice.

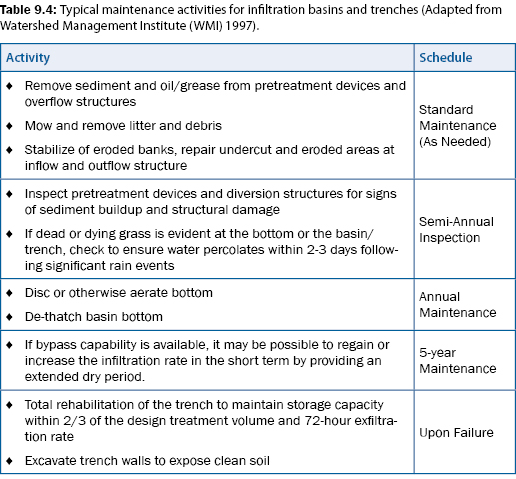

In order to maintain proper function and maximum pollutant removal, infiltration practices require regular maintenance and inspection. Table 9.4 provides guidance on typical maintenance practices and time frames.

If any method of assessment indicates unacceptable levels of infiltration in basins or trenches, any sediment layer or crust on the surface should be removed. If this does not sufficiently restore the practice, the filter fabric, if present, should be inspected and, if warranted, replaced. If infiltration rates do not increase to acceptable levels, the entire basin or trench should be renovated and/or replaced.

Permeable pavements

In order to remove accumulated sediment, permeable pavements should be inspected, vacuumed, and pressure washed at least three to four times per year (Landphair et al. 2000; NJDEP 2004). More frequent maintenance will be required in particularly dirty areas. Solids removed in this process must be disposed of as required by all governing regulations. If any level of assessment reveals inadequate infiltration capacity and vacuuming and washing does not rectify the situation, drilling of the surface may restore some capacity (Landphair et al. 2000). If drilling fails, the entire surface may have to be removed and replaced.

Frequency, effort, and cost

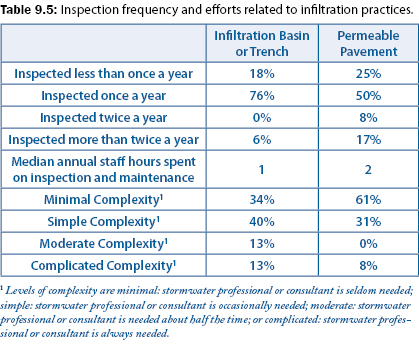

Survey results (Erickson et al. 2009) indicate that a majority of responding municipalities inspect their infiltration basins/trenches and permeable pavements once a year or more. It is recommended, however, to have regular and frequent inspection of infiltration practices. Detailed survey results related to inspection frequency are given in table 9.5.

The median annual staff-hours devoted to the inspection and maintenance of infiltration practices are also shown in table 9.5. Municipalities (Erickson et al. 2009) were also asked to gage the level of complexity of their maintenance efforts as either minimal, simple, moderate, or complicated. The percentage of respondents that selected the four categories is also shown in table 9.5.

The U.S. EPA (1999) estimated that typical annual operating and maintenance (O & M) costs for infiltration basins, as based on expected maintenance schedules, range from 1%-10% of the total construction cost. Weiss et al. (2007) reviewed the literature and found that, based on expected maintenance schedules and estimated prices, the expected annual O & M costs ranged from 2.8%-4.9% of the total construction cost. For infiltration trenches the corresponding values were 5%-20% (U.S. EPA 1999) and 5.1%-126% (Weiss et al. 2007). No such values were reported for permeable (or porous) pavements. It must be noted that these cost estimates are not based on actual O & M cost data but rather on typical maintenance schedules and activities combined with the estimated costs to perform these activities.

Factors affecting performance

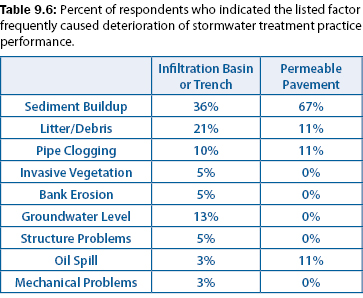

Maintenance efforts for infiltration practices are typically focused on removal of accumulated sediment and litter/debris. For a list of all factors that were deemed to frequently cause deterioration of stormwater treatment practice performance and the percent of responding municipalities (Erickson et al. 2009) that indicated the factor most frequently affected their stormwater treatment practices performance, see table 9.6. Landphair et al. (2000) note that the performance of an infiltration trench is expected to decrease with time as the void spaces in the surrounding native soil fill with fines from the runoff which has infiltrated.

Continue to Recommendations.