Additional considerations for automatic sampling

P.T. Weiss, A.J. Erickson, J.S. Gulliver, R.M. Hozalski, O. Mohseni, and W.R. Herb

Automatic sampling equipment

Stormwater sampling equipment is designed to collect samples either manually when triggered by the user or automatically when predefined criteria are met, with the aid of data loggers and computer software. Available equipment is summarized herein and discussed in greater detail in “Urban Stormwater BMP Performance Monitoring” (U.S. EPA 2002). Grab sampling equipment is also discussed in Stenstrom and Strecker (1993).

Automatic samplers, which collect and store water samples until they can be retrieved, are recommended for sampling suspended solids, phosphorus, nitrogen, salts, metals, and other pollutants that do not change or degrade rapidly. For pollutants that may undergo rapid transformation, such as temperature, fecal coliforms, and organic chemicals, it may not be possible to retrieve and analyze the samples before transformation compromises the sample integrity. For such pollutants, grab samples or rapid retrieval of automatically collected samples followed by prompt analysis are recommended to ensure accurate representation of the pollutant concentration. Alternatively, sample refrigeration or chemical preservatives can be used to reduce the rate at which pollutant transformation occurs. Consult an analytical methods manual (e.g., A.P.H.A. 1998b) to determine if refrigeration or preservatives will reduce transformation of pollutants and whether addition of preservatives will interfere with analysis of other pollutants of concern.

Automatic samplers do not require anyone to be present for sample collection; they can be programmed to begin sampling when a user-specified rainfall amount or intensity occurs (electronic rain gauge required), after a predefined depth or quantity of flow is achieved, or after some combination of conditions is met. They can also be programmed to collect varying sample sizes, collect samples at user-specified time intervals (i.e., time-weighted) or flow volume increments (i.e., flow-weighted), or collect samples over an entire runoff event that lasts two days or more.

Some automatic samplers are powered from an external 120-volt AC power source. Many locations, however, do not have an external power source and therefore most monitoring applications use automatic samplers that are powered by a deep-cycle, 12-volt battery. Solar panels are also available to recharge the batteries, provided that adequate sunlight is available and the solar panel is free from obstructions (e.g., snow, leaves, etc.). Another option is to use an additional battery as backup to the power supply.

Automatic samplers are available to collect discrete samples or composite samples. The sampling portion of an assessment program should be planned before sampling equipment is purchased to ensure the appropriate equipment is available and does not exceed the budget of the program. Automatic samplers with refrigerated sample storage compartments can be used to preserve the integrity of samples that degrade. For example, sample storage for dissolved phosphorus determination recommends refrigeration to reduce the transformation of dissolved phosphorus to particulate phosphorus, or vice versa (A.P.H.A. 1998a). Refrigeration units, however, require an AC power supply.

While samples must always be manually retrieved from the storage unit for analysis, some samplers and data loggers have modem or cellular connections that allow measurement data such as flow rate, water depth, and rainfall intensity to be retrieved without physically visiting the sampling location. Some systems also allow users to remotely determine whether samples have been collected. Manufacturers of automatic samplers (at the time this manual was written) include: EPIC/Stevens, Hach/Sigma, Isco, and Manning.

Equipment placement and maintenance

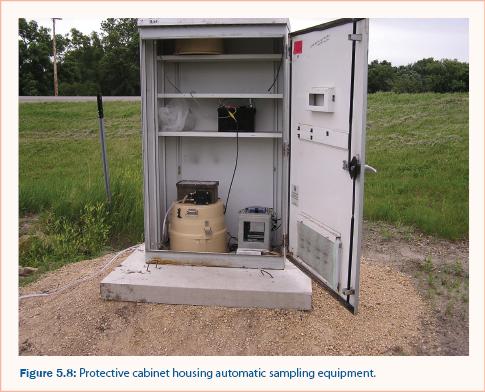

Placement of sampling equipment is site-specific and depends on a number of factors, including: equipment type, amount of equipment, availability of protective cabinets, type and design of stormwater treatment practice. As described in Water Budget Measurement, influent (or effluent) flow measurement and sampling is simplified if all stormwater inflow (or outflow) is routed to a single location. Placing sampling equipment near flow measurement equipment is advantageous because sampling is typically triggered by flow measurement equipment and all instrumentation can be housed in the same enclosure. An example of flow measurement and sampling equipment in the same location is shown in Figure 5.7, and a protective cabinet housing automatic sampling equipment is shown in Figure 5.8.

Automatic sampling equipment that remains in the field for long periods of time should be maintained at weekly intervals. Sampling equipment maintenance will vary, but manufacturer’s recommendations are typically provided and should be followed. Additional sampling bottles are available for purchase, and it is recommended to have at least two sets of sample bottles (one for the sampler and one for transporting samples to the analytical lab). More sets of sample bottles may be required, depending on the frequency of storm events and the processing time of the analytical lab.

It is important to recognize that some pollutants adsorb to the surface of collection bottles (organic compounds), degrade over time (coliforms), or may volatize (dissolved gases). These confounding processes can be minimized by choosing sample bottle material properly (e.g., plastic or glass) and cleaning sample bottles appropriately. Consult Standard Methods (e.g., A.P.H.A. 1998b) or the analytical lab performing the water quality analysis to determine whether the pollutants of interest for the assessment program will adsorb or degrade and which bottle material or preservation technique is recommended. If analyte degradation is a concern, then sample preservation (e.g., refrigeration), collection followed by rapid analysis, or both, may be necessary.

Care and cleaning of sampling equipment and bottles will prolong proper functionality and reduce analytical error. Sample bottles should be cleaned according to Standard Methods (e.g., A.P.H.A. 1998b). Depending on the pollutant, special procedures may be required to prepare the bottles for sampling. For example, sample bottles for metals or phosphorus should be acid washed, and sample bottles for coliforms should be sterilized (e.g., autoclaved). Refer to the analytical procedure for pollutants of interest, Analysis of Water and Soils, or the analytical lab that will process the samples for more information.

Winter sampling in cold climates

Stormwater treatment practices may function differently during the winter than during the summer. For example, a layer of ice in a wet pond can reduce the effective volume of the pond and cause short-circuiting, which will reduce hydraulic residence times and lower sediment removal rates. Some of the largest concentrations of pollutants in stormwater are found in late winter/early spring runoff (i.e., snowmelt). Unfortunately, it is not common to monitor winter runoff and snowmelt events, most likely due to the inherent challenges imposed by the weather.

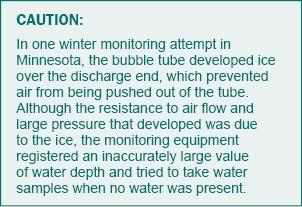

One winter challenge that must be overcome is the formation of ice in and around sampling lines and bubbler lines that are used for water depth measurement at weirs (see Open Channel Flow for recommendations). Ice formation in sampling lines can prevent samples from being collected. Ice formation over bubbler tubes will result in erroneously large pressure readings and inaccurate depth measurements. In addition, if an automatic sampler is installed to collect samples when the water depth exceeds a certain value, then a false pressure reading could trigger a sampling sequence when insufficient water depth is available. Because of this possibility, a pressure transducer is recommended to measure water depth. Caution must be exercised, however, because the flexible diaphragm inside a pressure transducer can be damaged by ice formation.

It is possible to maintain a charge on the batteries used to power the sampling and flow monitoring equipment during winter months with solar panels (Hussain et al. 2005). Solar panels should be faced toward the south and angled steeply (near vertical) to capture the most sunlight and to remain free of snow accumulation. Because of the potential problems of winter sampling, grab sampling is advised in conjunction with automatic sampling to ensure that appropriate samples are collected.

Automatic sampling of water containing suspended solids

The accuracy of automatic sampling of water that contains suspended solids has been documented (Reed 1981), and research is being conducted at the University of Minnesota’s St. Anthony Falls Laboratory to investigate the limits of sampling suspended solids and particulates and to improve sampling methods for automatic samplers. For more information, refer to Automatic sampling suspended solids.

Inaccurate sampling of suspended solids can lead to sedimentation-based stormwater treatment practices that are significantly larger and therefore more expensive to construct and maintain than required. For a detailed discussion on the importance of particle size distribution sampling, Particle Size Distribution.

Continue to Sample handling.