Synthetic Runoff Testing Sedimentation Practices

P.T. Weiss, A.J. Erickson, J.S. Gulliver, R.M. Hozalski

Synthetic runoff testing (level 3) can be used to estimate the infiltration rate (and subsequently runoff volume reduction), pollutant removal efficiency, or both, in sedimentation practices such as dry ponds, wet ponds, wet vaults, and proprietary devices (provided adequate access and water supply is available). Synthetic runoff test results can be used to develop an accurate characterization of pollutant retention or removal that can be used with natural runoff in numerical models for total daily maximum load (TMDL) assessments.

The primary constraint for synthetic runoff testing is the available water volume and discharge: fire hydrants can typically produce between 2 and 4 cfs for up to approximately 30 minutes and a water truck can produce up to approximately 1 cfs (0.028 m3/s). Most commercial water trucks hold approximately 500 ft3 (14,160 liters) of water, but a large water truck can hold up to 1000 ft3 (28,320 liters), allowing the maximum discharge for approximately 20 minutes. As demonstrated in example 10.1, synthetic runoff testing is generally possible for only smaller stormwater treatment practices.

Dry ponds

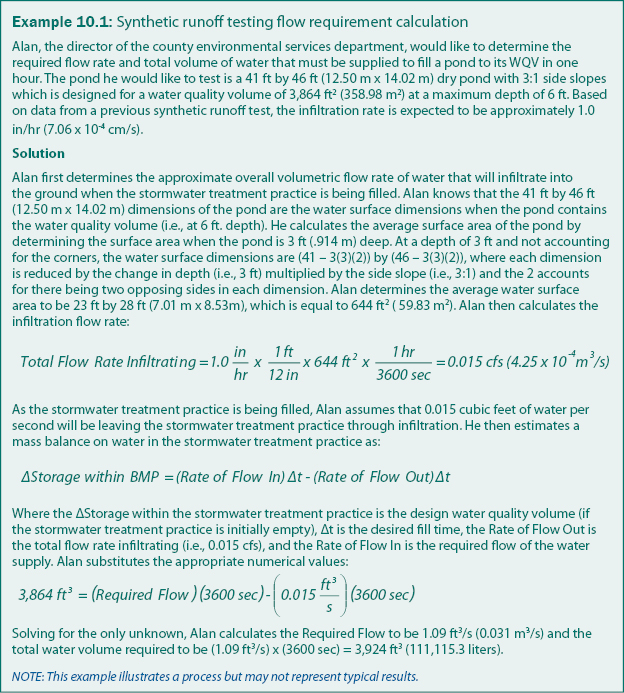

Synthetic runoff testing of dry ponds can be used to estimate the runoff volume reduction (by infiltration) and the removal of pollutants. Filling a dry pond with synthetic stormwater runoff and measuring the rate at which the stored runoff infiltrates into the soil can provide information used to estimate the runoff volume reduction for past or future natural runoff events. Synthetic runoff testing, however, requires that the synthetic water source (e.g., fire hydrant, water truck) can fill the dry pond with the design volume at a rate faster than water infiltrates into the soil. Expected infiltration rates are best determined with hydraulic conductivity tests (level 2) on the same stormwater treatment practice or from other relevant information about the practice (e.g., soil type, surface characteristics). If no information is available, however, estimates may be made from literature when possible. Example 10.1 illustrates how the required discharge and total volume of water for synthetic runoff testing is determined.

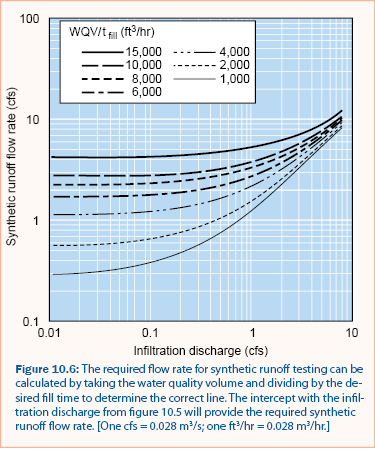

Figure 10.5 is a graph of the relationship between total infiltration discharge (cfs) and stormwater treatment surface area (ft2) for various infiltration rates (in/hr). Figure 10.6 is a graph of the relationship between the required synthetic runoff discharge (cfs) and infiltration discharge (determined from figure 10.5) for various ratios of water quality volume (ft3) and desired fill time (hr). Figures 10.5 and 10.6 can be used together as a graphical solution to estimate the required water supply discharge (i.e., synthetic runoff flow).

Returning to example 10.1, a graphical solution can be obtained using figures 10.5 and 10.6. Using figure 10.5, a pond with an infiltration rate of 1.0 in/hr (7.06 x 10-4 cm/s) and an average surface area of 644 ft2 (59.83 m2) will infiltrate approximately 0.015 cfs (4.25 x 10-4 m3/s). From figure 10.6, an infiltration discharge of 0.015 cfs and a water volume to desired fill time ratio of 3,864 ft3/hr (109.42 m3/hr) (i.e., WQV/tfill = 3,864 ft3/hr) would require a synthetic runoff discharge slightly higher than 1 cfs (0.028 m3/s). Estimation of the total volume of water required can be determined as demonstrated in the last calculation of example 10.1.

If the water supply used for synthetic runoff testing cannot produce the required flow, the fill time may need to be increased. The calculations in example 10.1 can be reversed and the amount of time required to fill the stormwater treatment practice can be calculated from the available water supply flow rate. Due to the increased loss of water through infiltration while filling the practice, a longer fill time, however, requires a larger total volume of water, which may exceed the limitations of the available water source.

Pollutant removal efficiency can be estimated by adding a well-characterized pollutant (e.g., sediment) to the synthetic stormwater and measuring the change in concentration with respect to time of the pollutant in the effluent of the dry pond. The accuracy of synthetic runoff tests for pollutant removal efficiency may be limited by difficulties in achieving a representative suspended-solids concentration through sampling (see Automatic sampling suspended solids for more information). For this type of synthetic runoff testing, the water source must be able to provide the design discharge for a period of time that allows flow through the sedimentation practice to fully develop and equilibrate. A simple comparison of the maximum flow rate of the sedimentation practice and the available water source can be used to determine if the water source is adequate.

Sediment retention testing of dry ponds estimates the volume of solids captured by sedimentation in the dry pond and, if measured with respect to time, can be used to estimate the sediment accumulation rate. Synthetic runoff tests(level 3), however, can estimate the infiltration rate, the pollutant removal efficiency, or both, and therefore determines very different stormwater treatment practice parameters than capacity testing (level 2).

Wet ponds

Synthetic runoff testing of wet ponds can be used to estimate the retention of pollutants. Wet ponds do not infiltrate a significant amount of stored runoff because they maintain a permanent pool of water even during long dry periods. Therefore, wet ponds only minimally reduce runoff volume by infiltration or evaporation. Pollutant removal efficiency can be determined by spiking the synthetic stormwater with a pollutant and then measuring the concentration of pollutant exiting the wet pond. The accuracy of these tests could be limited by difficulties in achieving a representative suspended-solids concentration through sampling (see Automatic sampling suspended solids for more information).

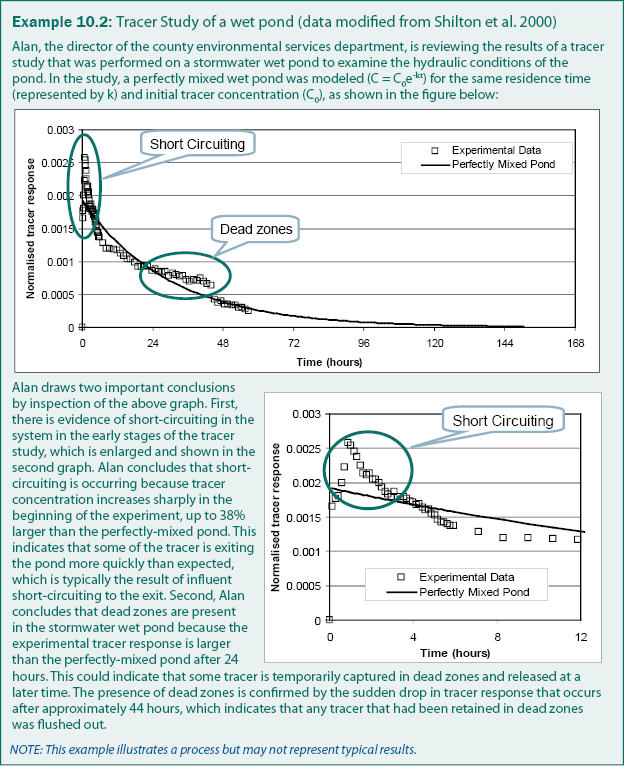

Synthetic runoff tests using a conservative tracer (e.g., chloride, rhodamine) can be used to investigate the hydraulic behavior of a wet pond. Tracer studies involve spiking the influent with the tracer and measuring the tracer concentration in the effluent as a function of time during a synthetic runoff event. Results from tracer studies, as illustrated in example 10.2, can be used to determine if stormwater is short-circuiting through the pond or if there are dead zones present. Short-circuiting in stormwater treatment occurs when stormwater passes through the pond with minimal or no treatment because of incomplete mixing. A poorly located inlet and outlet may result in a portion of the influent bypassing the treatment available in the pond. Another cause of short circuiting may occur during the winter in cold climates. Runoff or snowmelt that enters a frozen wet pond may flow over the top of the ice directly to the outlet structure. Short-circuiting can result in poor pollutant removal efficiency and is a common cause of wet pond failure. Dead zones are areas in a stormwater treatment practice where water becomes trapped and does not pass through the stormwater treatment practice as intended. For example, an underground proprietary device may have areas where stormwater circulates but is not released until the storm event is over or nearly over. Pollutants in the trapped water may or may not be removed by the proprietary device and, if not removed, may appear in the effluent samples towards the end of the runoff event. Pollutants can become trapped in dead zones between storm events and be released during subsequent storm events, which may result in negative removal efficiency (i.e., effluent pollutant > influent pollutant) for individual runoff events.

Underground sedimentation devices

Synthetic runoff testing can be used to estimate the retention of solids in a wet vault or proprietary device. Typically, proprietary devices neither infiltrate stored runoff nor have sufficient storage volume to reduce peak flow; thus, flow reduction testing of these devices is not relevant. The synthetic runoff, however, can be dosed with sediment to assess solids removal performance (Wilson et al, 2008). The solids removal performance is determined either by collecting and measuring sediment concentrations in effluent samples or by extracting and measuring the sediment retained by an initially clean device. The latter method is likely to be more accurate as all of the solids are collected and weighed, whereas the former analyzes only the sediment in discrete effluent samples from water exiting the device. See Automatic sampling suspended solids for a discussion of solids sampling.

Synthetic runoff testing (level 3), can also be used to estimate the hydraulic behavior (via conservative tracer), the pollutant removal efficiency, or both, and therefore determines very different stormwater treatment practice parameters than level capacity testing (level 2). A case study (Case Study #2) of synthetic runoff testing of a underground sedimentation device is given in Case Studies.

Continue to Monitoring.