Maintenance for Sedimentation Practices

P.T. Weiss, A.J. Erickson, J.S. Gulliver, R.M. Hozalski

Maintenance of sedimentation devices often involves sediment and trash removal, fixing clogged pipes, or addressing invasive vegetation. The performance of a sedimentation practice is often dependent upon the continuous maintenance activities undertaken. The practice will eventually lose the performance that it had as a new device unless it is maintained on a regular basis.

Actions

Dry ponds

Dry ponds can be effective at retaining suspended solids and pollutants that typically adsorb to solids. After continued operation, retained solids will eventually need to be removed. The dry pond must be regularly inspected to determine its condition. The required frequency of inspection and maintenance is dependent on the watershed land use (e.g. urban, rural, farm, etc.), construction activities present and rainfall amounts and intensity. It is recommended, however, that visual inspection and any associated maintenance be performed at least once per year.

If any level of assessment reveals that a dry pond is not draining a runoff event less than or equal to the design storm volume within the specified design time, the following measures should be taken.

- Inspect all outlet structures for clogging and/or structural damage. Remove debris and repair/replace outlet structure, if necessary.

- Inspect the outflow location(s) to make sure a tailwater condition is not impeding discharge from the pond. If this is the case, the tailwater should be eliminated or the outlet modified in such a way that drainage occurs within the desired time.

- If the pond still does not drain within the specified design time, the hydraulics of the pond should be reevaluated and the geometry and outlet structure redesigned.

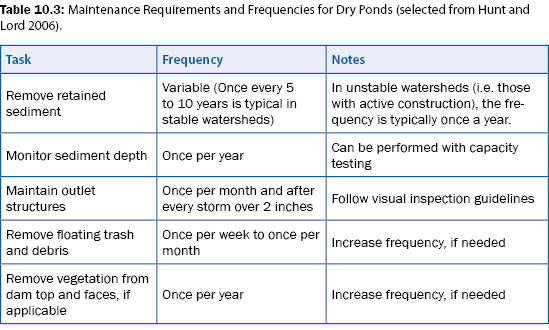

Hunt and Lord (2006) discuss the maintenance requirements of wetlands and wet ponds. Even though Hunt and Lord do not specifically discuss dry ponds, their recommendations that apply to both wet ponds and dry ponds are reproduced in Table 10.3.

Dry ponds are most effective in retaining suspended solids and pollutants that tend to adsorb to solids and are usually not implemented to reduce temperature impacts or achieve retention of dissolved pollutants. Thus, the following discussion only considers solids and pollutants which typically sorb to solids. If a dry pond is not retaining suspended solids (or other sorbed pollutants) at expected levels, the following steps should be taken.

- Check to make sure that the desired levels of pollutant retention are realistic. For example, if the target pollutant is total phosphorous and the runoff entering the pond contains a large fraction of dissolved phosphorous, large retention rates of total phosphorous may not be possible for a device that retains pollutant mostly by sedimentation. Or, if the sediment size distribution contains an uncharacteristically large fraction of fines, the hydraulic retention time may not be adequate to achieve the desired retention rate. If retention of the desired pollutant is not realistic, consider implementing another stormwater treatment practice to achieve desired results.

- Perform a sediment capacity test to determine the remaining sediment storage capacity of the pond. If there is no remaining capacity or if the capacity is nearly exhausted, the entrained sediment should be removed to allow for additional storage.

- If there is adequate storage capacity remaining in the pond and pollutant removal is still less than expected values, a tracer study should be performed to determine if short-circuiting is occurring. If short-circuiting is occurring, consider adding one or more baffles or retrofitting the pond to redirect the flow of runoff in a way that eliminates or minimizes short-circuiting.

Wet ponds

Wet ponds can be effective at retaining suspended solids and pollutants that typically adsorb to solids but are not as effective at retaining dissolved pollutants. After continued operation retained solids will need to be removed, thus the wet pond must be inspected regularly to determine its condition. The required frequency of inspection and maintenance is dependent on the watershed land use (e.g. urban, rural, farm, etc.), construction activities in the watershed and rainfall amounts and intensity. It is recommended, however, that visual inspection and any associated maintenance be performed at least once per year.

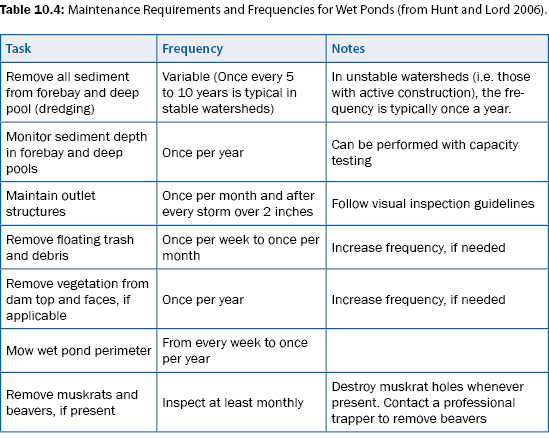

Hunt and Lord (2006) discuss the maintenance requirements of wetlands and wet ponds. The recommendations that apply to wet ponds are reproduced in Table 10.4.

Capacity testing, synthetic runoff tests, or monitoring are required to determine if a wet pond is retaining pollutants as expected. Wet ponds are most effective in retaining suspended solids and pollutants that tend to adsorb to solids and are usually not implemented to reduce temperature impacts or achieve retention of dissolved pollutants. If a wet pond is not retaining suspended solids or other sorbed pollutants at expected levels, the following steps should be taken.

- Check to make sure that the desired levels of pollutant retention are realistic. For example, if the target pollutant is total phosphorous and the runoff entering the pond contains a large fraction of dissolved phosphorous, large retention rates of total phosphorous may not be possible for a device that retains pollutant mostly by sedimentation. Or, if the sediment size distribution contains an uncharacteristically large fraction of fines, the hydraulic retention time may not be adequate to achieve the desired retention rate. If retention of the desired pollutant is not realistic, consider implementing another stormwater treatment practice to achieve desired results.

- Perform a sediment capacity test to determine the remaining sediment storage capacity of the pond. If there is no remaining capacity or if the capacity is nearly exhausted, the entrained sediment must be removed to allow for additional storage.

- If there is adequate storage capacity remaining in the pond and pollutant removal is still less than expected values, a tracer study should be performed to determine if short-circuiting is occurring. If short-circuiting is occurring, consider adding one or more baffles or retrofitting the pond to redirect the flow of water in a way that eliminates or minimizes short-circuiting.

Underground sedimentation devices

Underground sedimentation devices generally target the same pollutants as dry and wet ponds but, because they are typically located underground, they are used more often in urban areas where land space is less available. Compared to dry and wet ponds, underground sedimentation devices are typically smaller and have a lower design flow and total solid capture capacity.

If an underground sedimentation device is underperforming, the following steps should be taken.

- Inspect all outlet structures for clogging and/or structural damage. Remove debris and repair/replace outlet structure, if necessary.

- Inspect outflow location to make sure a tailwater condition is not impeding discharge from the device. If this is the case, the tailwater level must be lowered.

- If the device is perforated, check to make sure the perforations are not clogged with sediment or debris. Remove sediment and debris, if present.

- If the device is proprietary, contact the manufacturer

If assessment reveals that an underground sedimentation device is not draining as expected, the following steps should be taken.

- Inspect all outlet structures for clogging and/or structural damage. Remove debris and repair/replace outlet structure, if necessary.

- Inspect outflow location to make sure a tailwater condition is not impeding discharge from the pond. If this is the case, the tailwater must be eliminated.

- If the device is proprietary, contact the manufacturer.

Frequency, effort, and cost

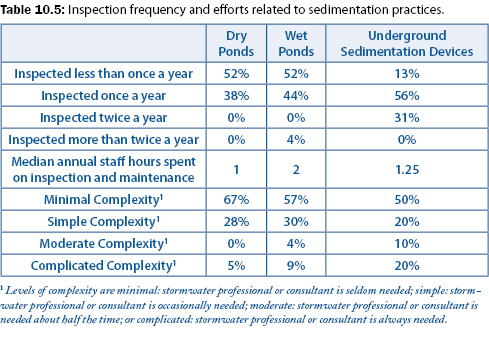

Adequate inspection frequency is dependent on many variables including rainfall amounts and intensity, watershed use, size of the practice, size of the sediment and sediment loads, and many other variables. Survey results (Erickson et al. 2009) indicate that the frequency of inspection for a majority of sedimentation practices of the responding municipalities is once a year or less. Details of the survey results (Erickson et al. 2009) related to the frequency on inspection of sedimentation practices are given in Table 10.5.

The median annual staff-hours devoted to the inspection and maintenance of sedimentation practices is also shown in Table 10.5 to be between one and two hours per site.

Municipalities were also asked to gage the level of complexity of their maintenance efforts as minimal, simple, moderate, or complicated (Erickson et al. 2009). The results given in Table 10.5 indicated that maintenance of sedimentations devices are the least complex of the practices considered in this manual.

The U.S. EPA (1999) estimated typical annual operating and maintenance (O & M) costs for dry ponds, as based on expected maintenance schedules, to be less than 1% of the total construction cost. Weiss et al. (2007) reviewed the literature and found that, based on expected maintenance schedules and estimated prices, the expected annual O & M costs for dry ponds ranged from 1.8%-2.7% of the total construction cost. For wet ponds the U.S. EPA (1999) did not report a value but the literature review of Weiss et al. (2007) found the range to be 1.9%-10.2% of the total construction cost. It must be noted that these cost estimates are not based on actual O & M cost data but rather on typical maintenance schedules and activities combined with the estimated costs to perform these activities. Based on the data in Table 10.5, the inspection and maintenance costs of underground devices are expected to fall between the inspection and maintenance costs of dry ponds and wet ponds.

Factors affecting performance

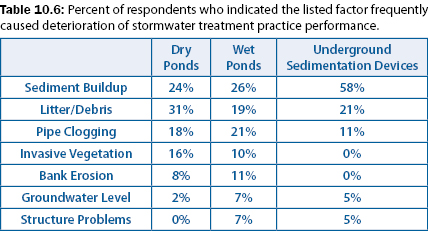

Maintenance efforts for sedimentation practices are typically focused on sediment and trash removal, fixing clogged pipes, and addressing invasive vegetation. Table 10.6 lists the percent of responding municipalities (Erickson et al. 2009) that indicated the listed factors most frequently caused deterioration of stormwater treatment practice performance. The most frequent factors causing deterioration of performance were sediment buildup, litter and debris, pipe clogging and invasive vegetation. Bank erosion, groundwater level and structural problems, however, can cause serious and rapid deterioration of performance when present.

Continue to Recommendations.